Aru Põllumajandus is a 20-year-old Estonian capital-based company with modern production technology and machinery. Their vehicles and agricultural machines have been purchased for the needs of the company, but transportation and mowing services are offered to others too.

The company has more than 3300 ha of arable land. The grain dryer, storehouses, machinery, and office of Aru Põllumajandus are in a small borough of Hulja in Kadrina Parish.

Challenge:

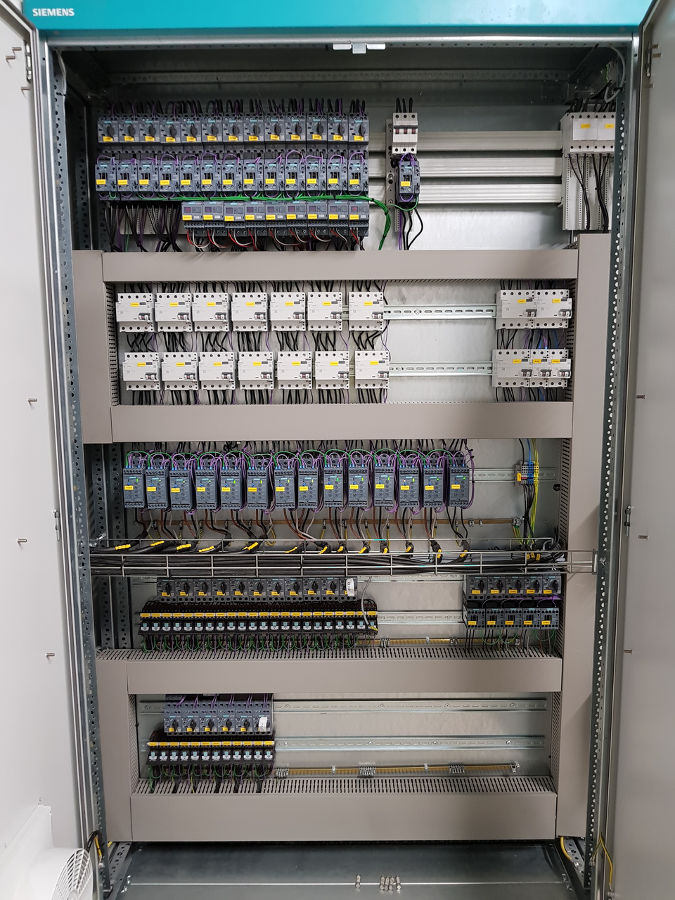

Due to the expansion of the grain silo warehouse, the upgraded complex with a total volume of more than 10 000 m3 needed a fully- automated management system. The old management system was not integral; according to the devices that were added, it had been divided between 11 distribution and automation control cabinets. Managing, adjusting and monitoring the new system had to be possible with a tablet and via SCADA. The SCADA system had to be able to log all technical and process parameters, but also send warning messages and alerts.

Result:

As a result, the devices of the grain complex are in one integral system that can be adjusted, managed and monitored on site and remotely via SCADA. Altogether there are more than 450 IO-signals, and 81 motors are being controlled, where the more critical ones have IO-Link technology based monitoring devices in the power circuit. Operators have a complete overview of all silos and ongoing processes. It is possible to monitor all system parameters and logs in the SCADA environment.

Thanks to the integral SCADA system, the number of faults due to human error has been decreased substantially. Now, it is possible to train new employees in a couple of weeks which was no option with the old and scattered system.

Client: ARU PÕLLUMAJANDUSE OÜ

Cooperation: TATOLI AS

Field: AGRICULTURE

Tasks completed during the project:

- Designing the automation solution

- PLC and HMI programming

- Integration of IO-Link devices

- Ignition SCADA programming

- Designing and manufacturing automation control cabinets

- Constructing a 5-meter-long 630A busbar set for the Siemens Busbar system

- Object assembly (cable lines, cables, control cabinets, frequency converters with a Profinet interface)

- Commissioning

- Preparing the documentation and circuit diagrams

Want to make your production more effective?

Atemix will get every factory into their best shape and help them keep it.