AS Emajõe Veevärk provides quality water services in 105 settlements in five counties. The objective of the company is to ensure long-term sustainable management of the water supply service based on the principle of economic use of resources and to offer a high-quality public water supply and sewerage service to the population.

AS Emajõe Veevärk wishes to raise awareness of water management and to be an opinion-former in the regional water sector as well as a competence centre for water management in merged local authorities. In co-operation with local governments and other water management companies, they aim to promote socio-economic regional development with their business activities.

The challenge:

The client wanted to upgrade the existing SCADA system. Keeping in mind the ultimate objective and in co-operation with the client, we developed a solution tailored to the specific needs of the client.

In the initial phase of the project, we had approximately one month to gather all the data necessary for the implementation of the project. At first, there was no clear understanding of how the existing parts of the system – network, servers, remote management network – were structured, which made it difficult to find information from the existing SCADA system.

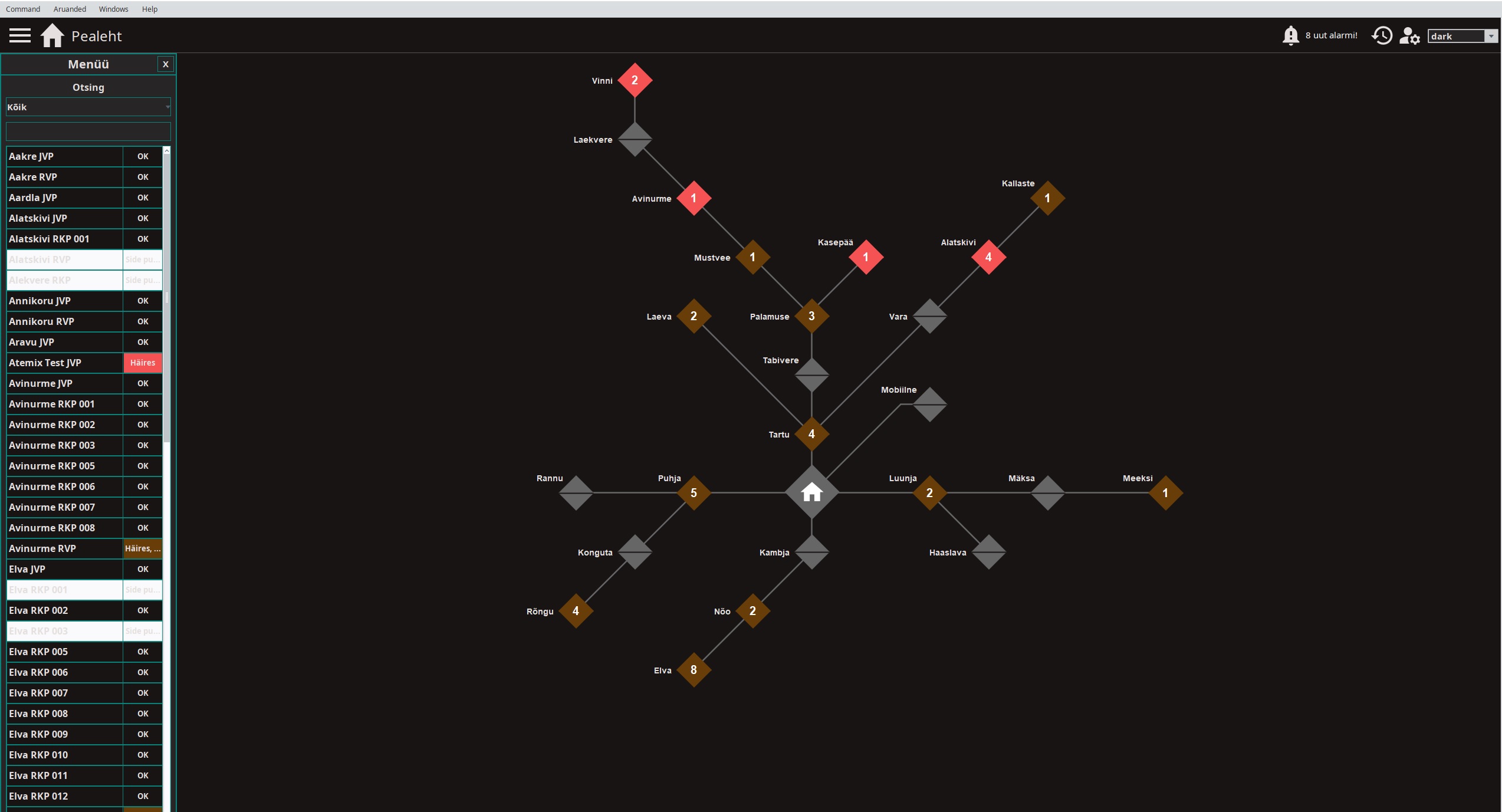

The volume of the work also made the whole process more complex. In total, there were approximately 250 sites from which we had to retrieve data and transfer them to the new SCADA system.

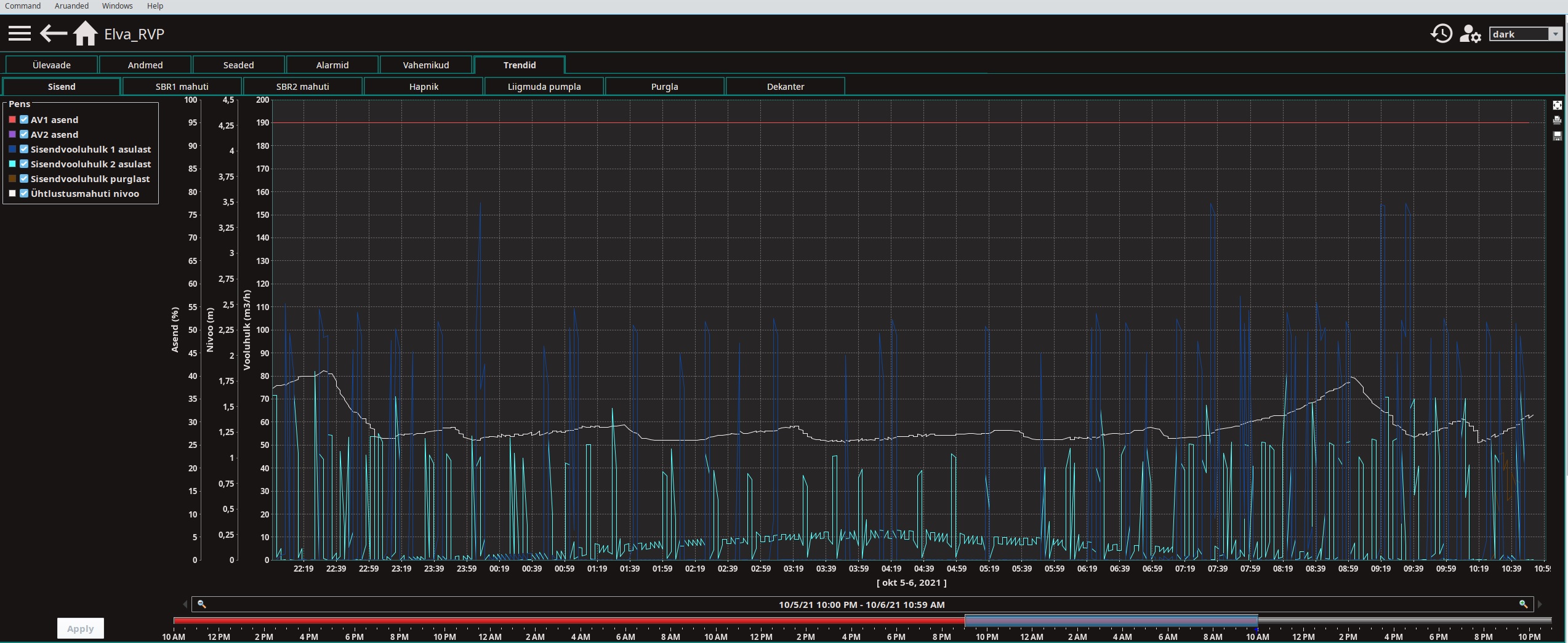

Our objective was to create a modular SCADA system based on documented information, which is also structured, standardised, has an unlimited number of users and can be accessed from mobile devices.

Which problems did Atemix have to solve in carrying out its work?

In the course of our work, we checked all sites and variables and their importance in the system. If previously the technician was called on site with every alarm, then now it is possible to determine based on the input information whether the problem can be solved remotely or on site.

Access to the system was limited to two VPN connections. We made the system more accessible so that every technician has their own tablet which contains information about the area, can be accessed from everywhere and used in the performance of their work.

The new system has an open architecture and is based on documented information. Thanks to this, the client can order system development and maintenance work from different service providers. We made sure that every site and device had its own appropriate licences, accesses, and documentation.

Result:

- An unlimited number of users, variables and connections.

- Mobile access to data from anywhere through Ignition Perspective.

- Standardised data and visual interface on all sites.

Our aim was to create two environments, meaning SCADA is a complete system comprising two separate SCADA environments: Ignition Perspective is intended for access through mobile devices and web browsers, whereas Ignition Vision is a full SCADA environment which can only be used on a computer; however, it can carry out all operations that SCADA offers, from management and changing of parameters to data analysis and compilation of reports.

The SCADA system that we developed is fully based on documented information. Singular variables were treated as standardised elements. Thanks to this approach, we were able to create a system that is based on modularity, not individual solutions.

What are the biggest benefits of the new SCADA system for the client?

The new SCADA system allows AS Emajõe Veevärk to use the SCADA environment via mobile devices without any user restrictions. Previously, the SCADA system was used via VNC Viewer; however, since there were only two operator computers, only two people could use SCADA at the same time.

The great merit of the new system is the reliability of its information. In the case of problems, relevant persons will receive an alarm notification and can use it to determine whether the problem can be solved remotely or on site.

SCADA significantly saves costs on maintenance trips which can be avoided. Thanks to precise information, the nature of the problem can be identified remotely and not every problem requires on-site maintenance.

Thanks to the modularity, open architecture of the system and proper documentation, the client has free choice as to which service provider they will use to conduct expansion, maintenance and upgrade works.

Client: AS EMAJÕE VEEVÄRK

Area: WATER MANAGEMENT

Work completed during the project:

- We obtained all appropriate accesses, servers, and licences.

- We used data from the old SCADA system to identify links and patterns.

- We created a concept that ensures the necessary functionality for the client and meets the requirements.

- We mapped 250 sites and in the process identified the necessity, functionality, characteristics and purposes of each variable. The variables ranged from 30 to 300 based on the site. There were some sites that overlapped, but despite that it involved a lot of work.

- We developed a completely new design solution which we presented to the client and obtained their approval.

- We stored and documented all our work during the project.

- We visualised all mapped sites and entered them into the new SCADA system.

- We developed standards for interfacing sites with SCADA.

“Our co-operation with AS Emajõe Veevärk was smooth and successful as the client helped us establish an understanding of the mechanisms of water management and provided constructive feedback during the project. Thanks to the co-operation we were able to create solutions that met the ultimate objective of AS Emajõe Veevärk – to make the SCADA system more user-friendly and optimise work processes. We are very grateful for their co-operation and the experience gained.”

Mikk Varik

CEO of Atemix

Want to make your production more effective?

Atemix will get every factory into their best shape and help them keep it.